Brazilian group visits major European institutions in Innovation Mission

Functionality, technology and sustainability. These were the main concepts that marked the Benchmarking in Innovation Mission that took place November 6 to 11 in Portugal and Italy. The initiative by Texbrasil, the Brazilian Fashion Industry Internationalization Program, developed by Abit in partnership with Apex-Brasil (Brazilian Trade and Investment Promotion Agency), took 12 companies to Europe to take part in a series of technical visits to important centers of research and innovation.

The first stage of the mission visited Portugal. There, representative from Audaces, Anfra, Coteminas, Digitale Textil, Lepper, Moovexx, PH FIT, Rhodia, Santanense, Sapeka, SENAI-Blumenau and Tekla visited technological centers focused on nanotechnology and smart materials, such as CITEVE (Technological Center of the Textile and Apparel Industries of Portugal) and CeNTI (Centre for Nanotechnology and Smart Materials), located in the city of Vila Nova de Famalicao.

The group of executives also participated in the 1st Luso-Brazilian Textile Innovation Workshop in Portugal. There they learned about the International Fibrenamics Platform, a connection between universities, companies and society, which began with the need to pragmatically transfer knowledge.

According to Roger Guenther, a representative for Santanense, the mission showed how advanced research institutions are in terms of nanotechnology applied to the textile industry. He also touched on the importance of missions as a way to access all of so many new things. “In addition to creation of a network of contacts with international companies and institutes, these events also allow for the teachings we’ve gained here to be applied in the company. We are already looking at the possibility of adopting spray flame retardant finishing at Santanense,” he adds.

Edson Souza, innovations manager at PH Fit, echoes his colleague’s opinion. “What is most valuable in this mission is granting companies of all sizes access to information and state-of-the-art technology, which will allow for development and innovation in most of the Brazilian textile chain,” he says.

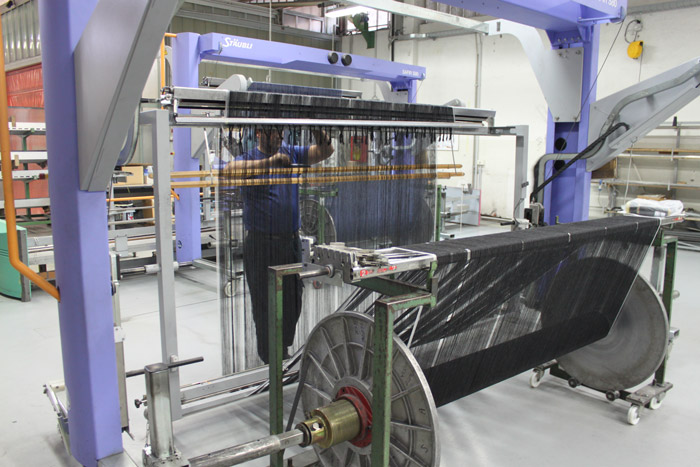

After the group’s experiences in Portugal, they continued on to Milan, Italy. There the executives saw institutions focused on quality control analysis and testing, while also visiting factories making design-focused fabrics, companies with significant operations in the auto industry and companies producing chemical auxiliaries and inputs for pre-treatment and covering of textile products.

One notable visit was to POLI Design, a service and information center connected to Politecnico di Milano, whose research is geared exclusively towards private and public companies. In the institution’s portfolio of projects is a project done in partnership with SENAI-Blumenau, where research was done in 2013 on tilapia leather, which had previously been discarded by the fishing industry and is now used in fashion items. To end the mission, Professor Conti, of POLI Design, went with the group to the city of Borgosesia, known for its great wool production in the XIX century.

Mario Schick, the director of Digitale Textil, said that missions like these are fundamental for the Brazilian fashion industry. “We have access not only to what is happening in other markets, but also to other companies’ research and experiences. This exchange enriches our perception of how we can improve our processes and products,” he says in closing.

Missão de Inovação